China Manufacturer of Automotive PP Honeycomb Panels for Durability

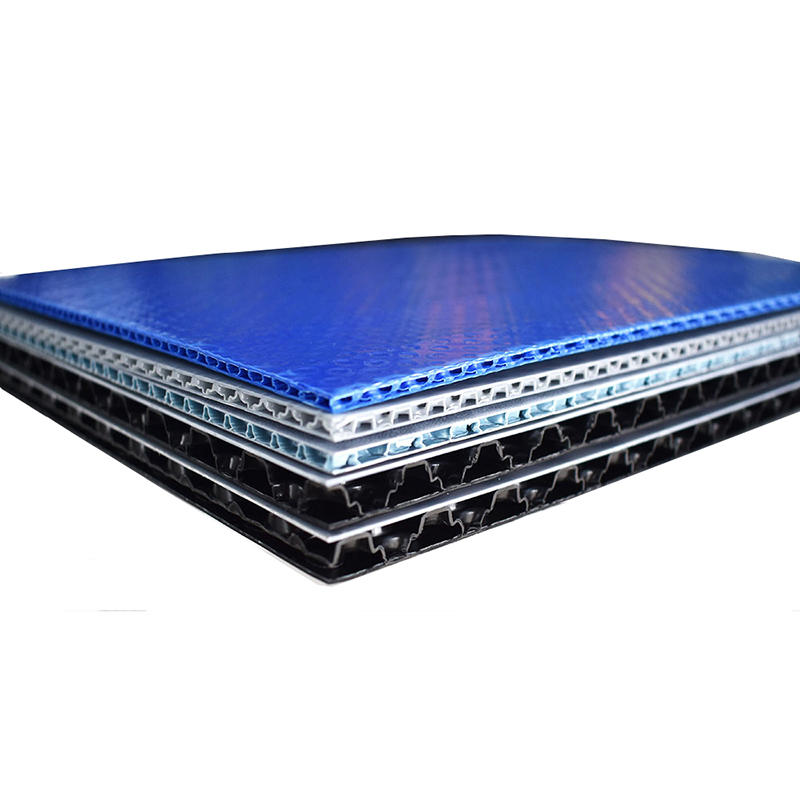

Navigating the world of automotive components, I’ve found that automotive pp honeycomb panels truly stand out for their lightweight and durable properties. Manufactured here in China, these panels make an excellent choice for various automotive applications, from interior structures to exterior panels. Their unique honeycomb design not only enhances strength but also significantly reduces weight, leading to improved fuel efficiency and overall performance. As a B2B purchaser, you’ll appreciate our commitment to quality and innovation. Our manufacturing processes ensure that each panel meets rigorous standards, allowing you to trust the safety and reliability of the products you source. Whether you're looking to enhance your production line or seeking cost-effective solutions, our automotive pp honeycomb panels provide the ideal blend of functionality and performance. Let’s work together to meet your needs and boost your business efficiency!

automotive pp honeycomb panel Stands Out Where Service Meets Innovation

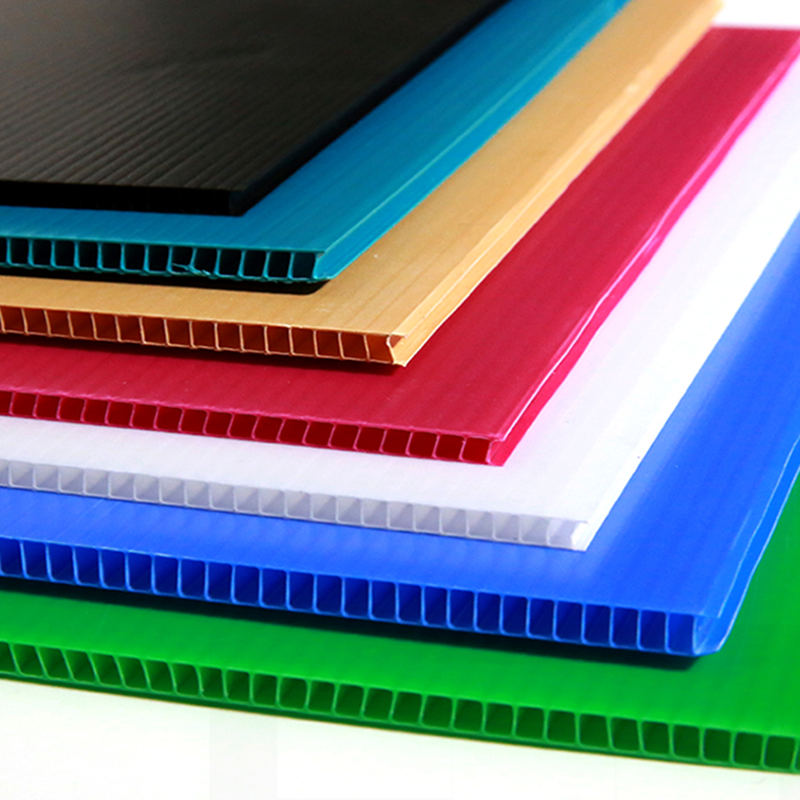

Automotive industry standards are continuously evolving, pushing manufacturers to seek innovative solutions that enhance performance, efficiency, and sustainability. One such breakthrough is the automotive PP honeycomb panel, a game-changer that combines lightweight properties with remarkable durability. This product stands out by effectively reducing vehicle weight while maintaining structural integrity, thus improving fuel efficiency and reducing emissions. As the global market moves towards greener alternatives, implementing these advanced materials is not just an option; it's becoming a necessity for competitive edge. The unique design of the honeycomb structure creates a high-strength panel with excellent impact resistance, making it ideal for various automotive applications. Its versatility allows for customization in size, thickness, and density, catering to the specific needs of different vehicle models and manufacturing processes. Additionally, the use of polypropylene enhances waterproof and thermal resistance, which contributes to overall vehicle longevity and performance. This innovative approach illustrates a perfect blend of service and technology, addressing the complexities faced by procurement professionals who prioritize quality and sustainability. Incorporating automotive PP honeycomb panels into production lines not only meets compliance with industry regulations but also aligns with global initiatives for environmental responsibility. As manufacturers strive to create lighter, safer, and more efficient vehicles, such innovations are essential in shaping the future of automotive design and engineering. By harnessing these advanced materials, companies can ensure they lead in a competitive marketplace, offering products that resonate with the demands of modern consumers and the imperative for sustainability.

Automotive PP Honeycomb Panel Stands Out Where Service Meets Innovation

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Lightweight | Made from high-performance polypropylene, reducing overall vehicle weight. | Improves fuel efficiency and lowers emissions. | Used in automotive interiors and exteriors for panels and components. |

| Durability | Resistant to moisture, chemicals, and UV rays. | Long lifespan with reduced maintenance costs. | Ideal for exterior trim and underbody components. |

| Customizable | Can be molded into various shapes and sizes. | Flexibility in design allows for innovative applications. | Used in bespoke vehicle designs and modifications. |

| Recyclable | Made from recyclable materials, supporting sustainability efforts. | Reduces environmental impact and promotes circular economy. | Adopted by eco-friendly automotive manufacturers. |

Related Products