China Manufacturer of Honeycomb Aluminium Panels & Aluminum Core Panels

When I think of high-quality construction materials, China honeycomb aluminium panels and aluminum honeycomb core panels immediately come to mind. These innovative products stand out for their lightweight yet robust design, making them perfect for a wide range of applications, from architecture to transportation. As a manufacturer, I take pride in using advanced techniques to ensure durability and strength, which our clients value immensely. What truly sets these panels apart is their excellent thermal insulation and soundproofing properties. This means that whether you are working on residential or commercial projects, you can rely on our panels to deliver both performance and efficiency. Additionally, the aesthetic appeal of the aluminium surface allows for versatile designs that meet diverse client needs. If you are a B2B purchaser seeking reliable materials that combine elegance and functionality, my China honeycomb aluminium panels will surely exceed your expectations. Let’s collaborate to elevate your projects to the next level!

China Honeycomb Aluminium Panels and Aluminum Honeycomb Core Panel Now Trending Guarantees Peak Performance

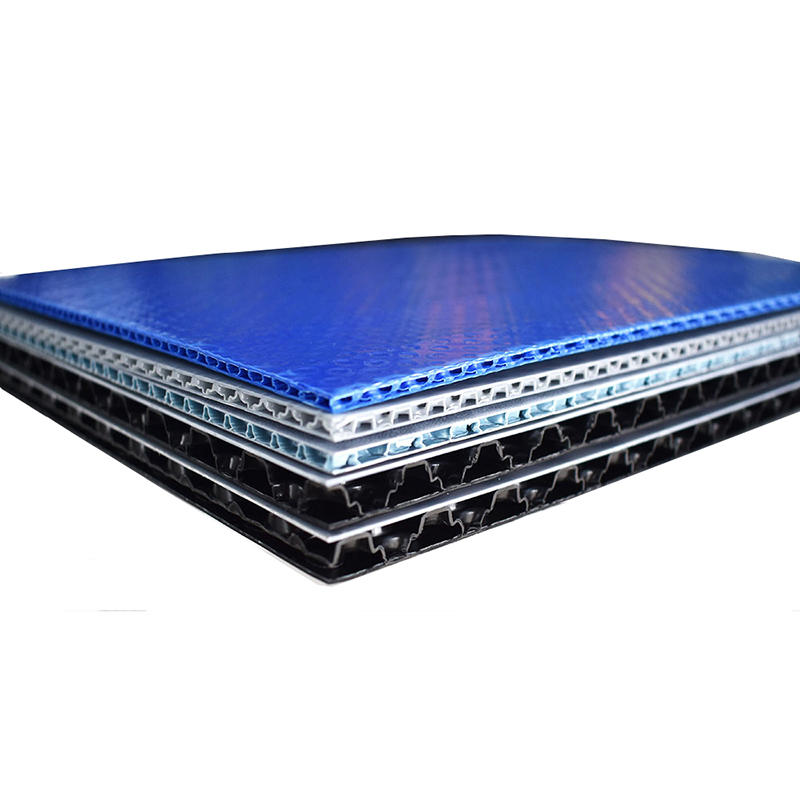

In recent years, China has emerged as a leader in the production of honeycomb aluminum panels and aluminum honeycomb core panels, capturing the attention of global buyers seeking innovative, lightweight, and durable materials for a variety of applications. These panels have become a staple in industries ranging from construction to transportation due to their exceptional strength-to-weight ratio, versatility, and cost-effectiveness. The trend towards these materials is driven by their ability to enhance energy efficiency and reduce overall project costs, making them an attractive option for architects, builders, and manufacturers. Aluminum honeycomb panels are characterized by their unique structure, which consists of a core made of hexagonal cells sandwiched between two thin layers of aluminum. This design not only minimizes weight but also maximizes structural integrity, making it ideal for facades, interior partitions, and even aerospace applications. As sustainability becomes increasingly important, these panels also provide environmentally friendly alternatives, as they are recyclable and produced with energy-efficient methods. As the demand for high-performance building materials continues to grow, sourcing honeycomb aluminum panels from China ensures access to cutting-edge technology and innovations in manufacturing. For global procurement specialists, investing in these trending materials guarantees peak performance, setting projects apart with their modern aesthetic and functionality. Embracing honeycomb structures opens doors to new possibilities in design and application, solidifying their position as a must-have material for forward-thinking industries.

China Honeycomb Aluminium Panels and Aluminum Honeycomb Core Panel Now Trending Guarantees Peak Performance

| Property | Details |

|---|---|

| Material | Aluminum Alloy |

| Thickness | 3mm to 30mm |

| Core Structure | Honeycomb |

| Maximum Load Capacity | 250kg/m² |

| Thermal Conductivity | 50 W/m·K |

| Applications | Aviation, Construction, Interior Design |

| Fire Rating | Class A (Non-combustible) |

| Weight | 4.5 kg/m² |

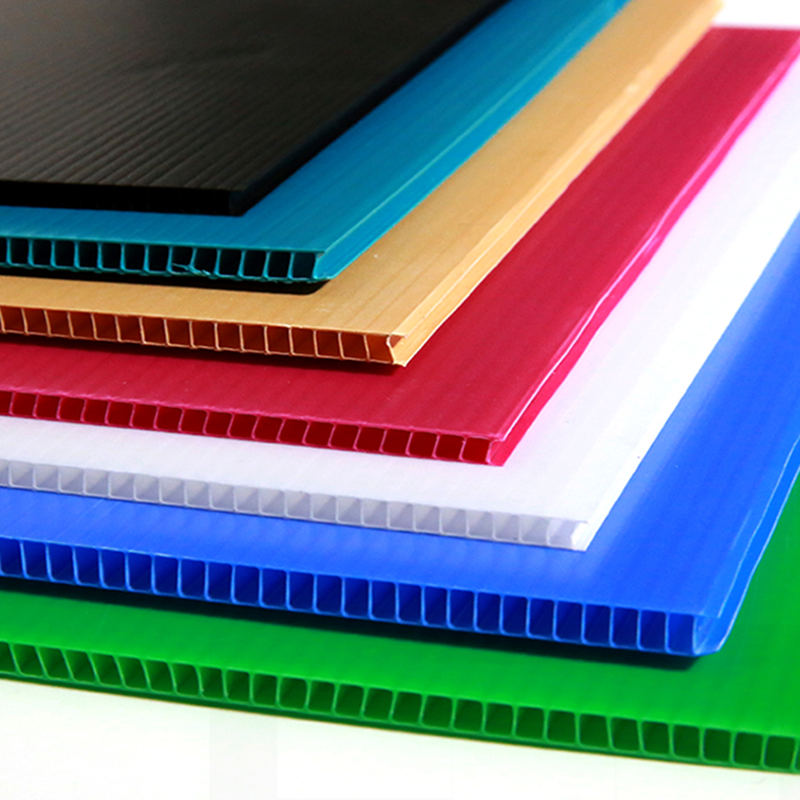

| Color Options | Silver, Black, White, Customized |

Related Products