China OEM China Plastic Sheet Making Machine

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for China OEM China Plastic Sheet Making Machine, To find out more about what we could do for you personally, call us anytime. We look forward to setting up good and long-term company interactions along with you.

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for China PVC Foam Board Extruder Machine and Extrusion Machine, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

|

Thickness |

1mm – 5mm |

5mm – 12mm |

15mm – 29mm |

|

Density |

250 – 1400 g/m2 |

1500 – 4000 g/m2 |

3200 – 4700 g/m2 |

|

Width |

Max. 1860mm |

Max. 1950mm |

Standard 550, 1100mm |

|

Max. 1400mm |

|||

|

Color |

Grey, white, Black, Blue, and etc. |

||

|

Surface |

Smooth, matt, rough, texture. |

||

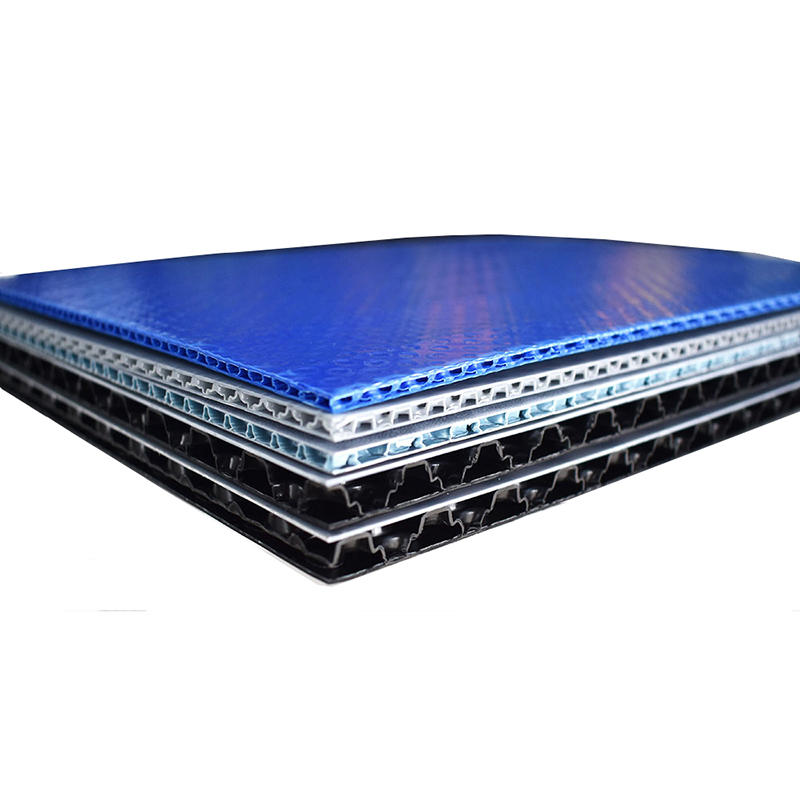

1. Strong compressive and impact resistance:

PP honeycomb board absorbs external forces, thus greatly reducing the damage caused by impact and collision. It is widely used in many fields such as automobile bumper and sports protective equipment.

2. Light weight and material saving:

According to the excellent mechanical performance, the PP honeycomb board can achieve the same effect with less consumables, low cost and light weight, greatly reduce the load weight of transport.

3. Sound insulation performance is superior:

Effective resistance to sound transmission and therefore can be used to soundproofing equipment for mobile vehicles and other transporting facilities.

4. Excellent heat insulation performance:

PP honeycomb board has excellent heat insulation performance, which can effectively block the heat transmission, and makes the internal temperature relatively stable.

5. Water resistance and strong corrosion resistance:

Due to the characteristics of its raw materials, it can be used for a long time in environments with high water content and strong corrosion.

6. Green and environmental protection:

Energy saving, 100% recyclable, VOC and formaldehyde free in the processing.

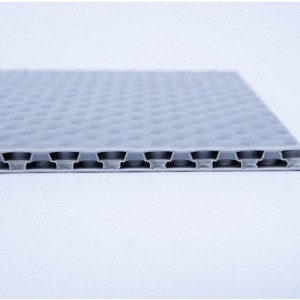

Polypropylene honeycomb board is also named PP cellular board / panel / sheet. It is made up of two thin panels, firmly bonded in a layer of thick honeycomb core material on both sides. According to the excellent mechanical performance, PP honeycomb board is widely applied to the shell, ceiling, partition, deck, floor and inner decoration for motor vehicles, yacht, and train.

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for China OEM China Plastic Sheet Making Machine, To find out more about what we could do for you personally, call us anytime. We look forward to setting up good and long-term company interactions along with you.

China OEM China PVC Foam Board Extruder Machine and Extrusion Machine, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.