China Manufacturer of PC Hollow Section Plate Extrusion Line Solutions

As a leading expert in the field, I understand the pressing need for high-quality equipment in the extrusion industry. Our China PC Hollow Section Plate Extrusion Line stands out with its advanced technology and impeccable build quality, ensuring you get the best results for your production needs. Being a manufacturer in China, we prioritize durability and efficiency, perfect for those aiming to enhance their output without compromising quality. This extrusion line is designed for easy operation and maintenance, which means less downtime and more productivity. With a focus on customer satisfaction, I can assure you that our equipment meets international standards and can be tailored to fit your specific requirements. Join the many B2B purchasers who trust us for their extrusion needs, and experience the difference in performance and reliability with our China PC Hollow Section Plate Extrusion Line. Your investment is set to yield great returns in a competitive market!

China PC Hollow Section Plate Extrusion Line Sets the Industry Standard Service Backed by Expertise

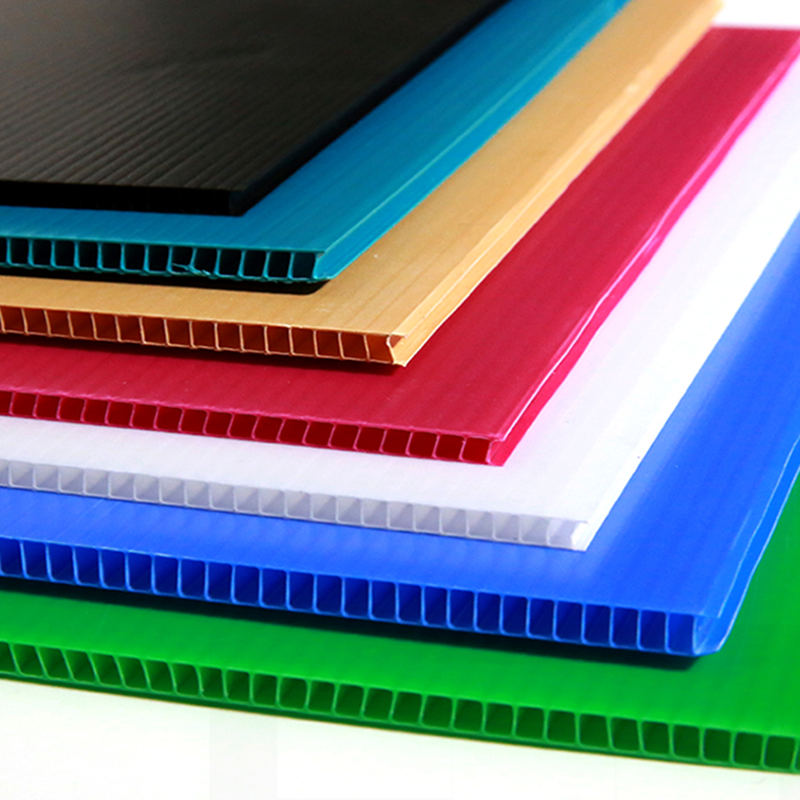

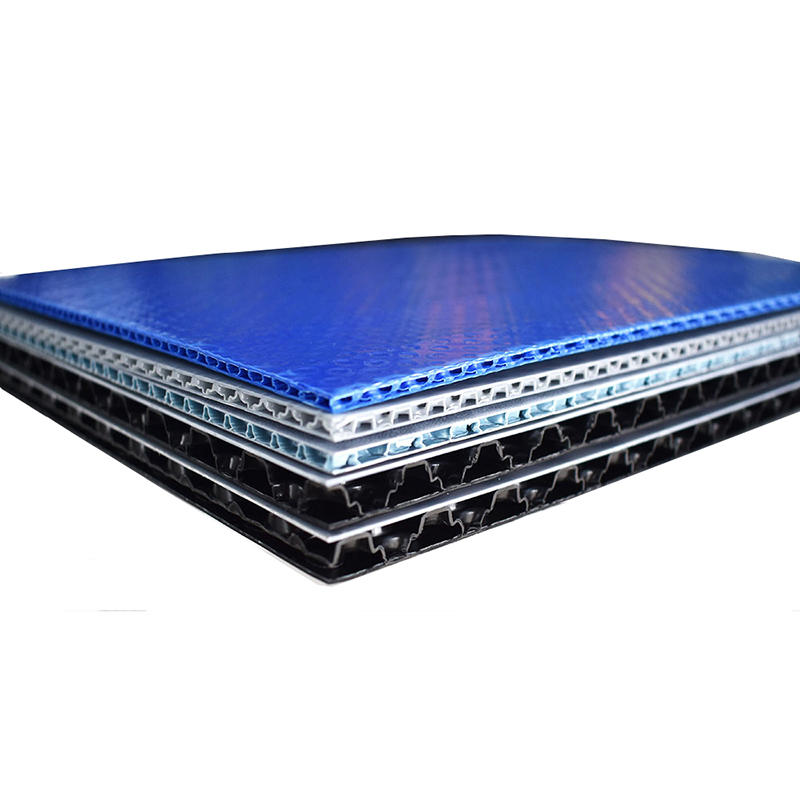

The China PC Hollow Section Plate Extrusion Line represents a significant advancement in manufacturing technology, setting a new benchmark for quality and efficiency in the industry. This innovative production line is designed to meet the diverse needs of global buyers, providing a robust solution for creating high-performance hollow section plates. Its state-of-the-art design ensures optimal output with minimal waste, making it an ideal choice for businesses aiming to enhance their production capabilities while maintaining cost-effectiveness. With a focus on expertise and service, our team offers comprehensive support throughout the procurement process. From the initial consultation to post-installation assistance, clients can rely on our extensive knowledge to ensure seamless integration of the extrusion line into their existing operations. The emphasis on high-quality materials and precise engineering guarantees reliable performance and durability, empowering manufacturers to deliver superior products to their customers. As industries increasingly demand sustainability and efficiency, the PC Hollow Section Plate Extrusion Line is poised to take center stage. By choosing this advanced technology, buyers can not only improve their operational efficiency but also contribute to a more sustainable future through reduced energy consumption and minimized environmental impact. Investing in this state-of-the-art equipment allows businesses to stay competitive in a rapidly evolving market, ensuring they remain leaders in their respective fields.

China PC Hollow Section Plate Extrusion Line Sets the Industry Standard Service Backed by Expertise

| Specification | Material | Production Capacity (kg/h) | Dimensions (mm) | Energy Consumption (kWh) |

|---|---|---|---|---|

| Hollow Section Plate A | PC (Polycarbonate) | 300 | 2000 x 1000 x 5 | 50 |

| Hollow Section Plate B | PC (Polycarbonate) | 250 | 2500 x 1200 x 6 | 55 |

| Hollow Section Plate C | PC (Polycarbonate) | 400 | 3000 x 1500 x 7 | 60 |

Related Products