Honeycomb Board Manufacturers in China: Quality & Innovation Insights

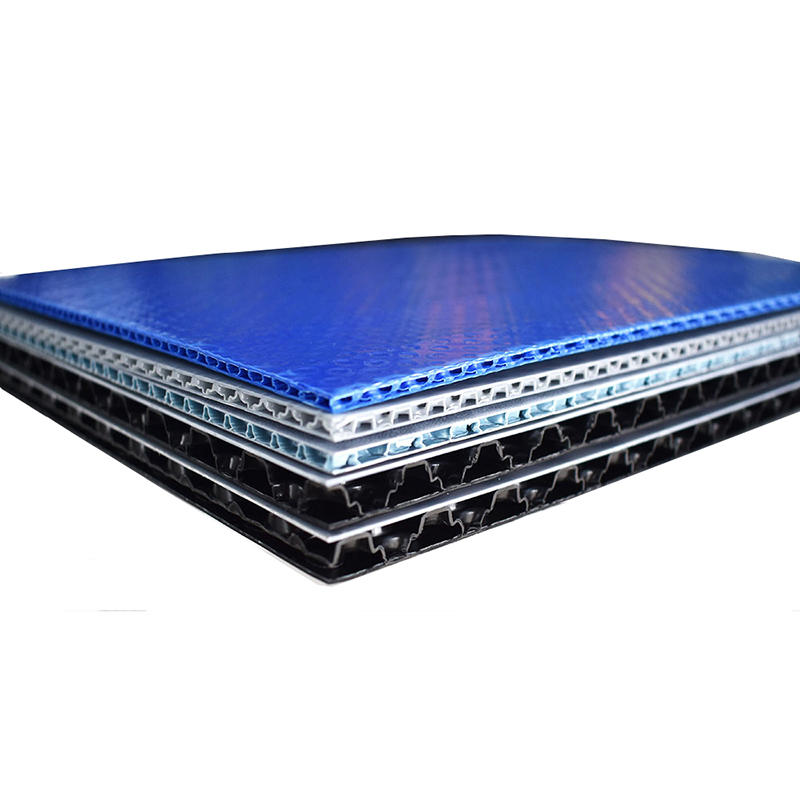

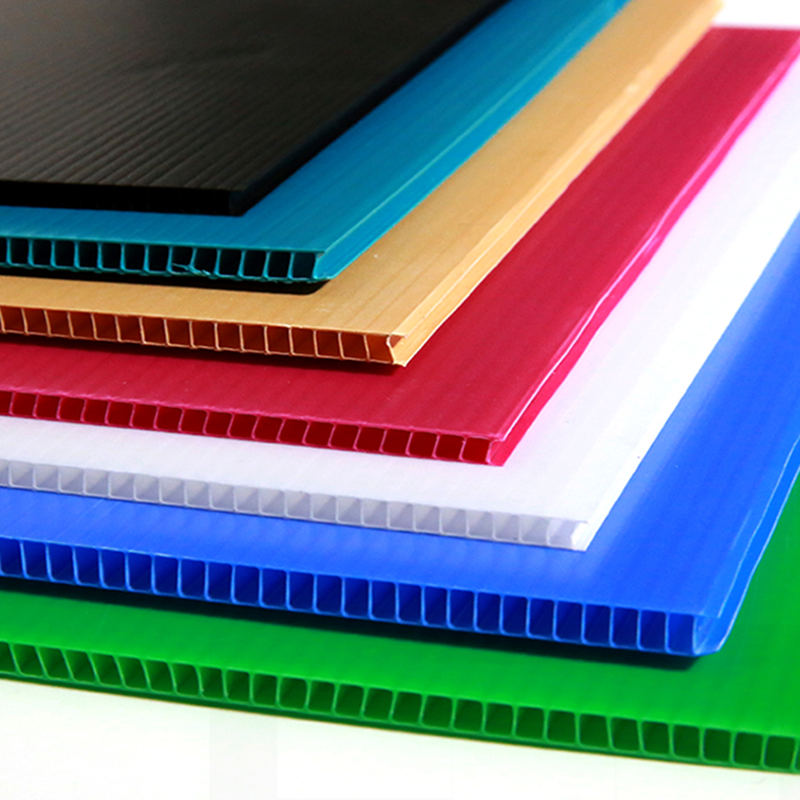

Are you in search of high-quality Honeycomb Boards? I've got just what you need! Our products, made in China, offer exceptional strength while being lightweight, making them ideal for various applications in the construction and packaging industries. As a manufacturer, we take pride in our ability to meet diverse customer requirements and tailor our honeycomb boards to suit specific needs. Whether you’re looking to enhance the durability of your products or need reliable material that won’t weigh you down, our honeycomb boards are the perfect solution. With our advanced manufacturing techniques, we ensure consistent quality and performance in every sheet. I invite you to check out our range of options and see how our honeycomb boards can elevate your business operations. Let's work together to find the right materials that fits your projects and budget!

Honeycomb Board Winning in 2025 Where Service Meets Innovation

In the dynamic landscape of the materials industry, honeycomb boards are poised to revolutionize how businesses approach sustainable construction and efficient design. The year 2025 promises to be a crucial turning point, where innovation not only enhances product performance but also intertwines seamlessly with exceptional service. As global demand for lightweight, durable materials grows, honeycomb boards are emerging as a leading choice for architects and engineers looking to balance strength and sustainability. Advancements in manufacturing technology are unlocking unprecedented possibilities for customization and versatility in honeycomb board applications. From aerospace and automotive designs to modern interior aesthetics, the adaptability of these boards allows for creative solutions that cater to a wide spectrum of industry needs. Coupled with a commitment to exemplary customer service, suppliers can ensure that their clients not only receive high-quality products but also guidance throughout the planning and implementation phases. As the marketplace shifts towards eco-friendly practices, the honeycomb board stands out as a symbol of responsible innovation. By reducing material waste and energy consumption, these boards are contributing to a greener future. As we look ahead to 2025, the integration of cutting-edge technology and enhanced service model will undoubtedly position honeycomb boards at the forefront of industry trends, making them an indispensable asset for procurement professionals worldwide.

Honeycomb Board Winning in 2025: Where Service Meets Innovation

| Feature | Description | Impact | Innovation Type |

|---|---|---|---|

| Lightweight Structure | Utilizes advanced materials to ensure durability without added weight. | Improves efficiency in transport and installation. | Material Innovation |

| Eco-Friendly Production | Manufactured using sustainable methods and recyclable materials. | Reduces environmental impact and appeals to eco-conscious consumers. | Sustainable Innovation |

| Customizable Designs | Flexible options for size, shape, and finish to meet diverse client needs. | Enhances customer satisfaction and applicability across various projects. | Design Innovation |

| Thermal Insulation | Offers superior insulation properties for energy efficiency. | Lowers heating and cooling costs for end users. | Functional Innovation |

| Quick Assembly | Designed for fast, no-tools assembly to reduce labor time. | Optimizes project timelines and budgets. | Process Innovation |

Related Products