Honeycomb Plastic Sheet Manufacturer in China | Quality & Durability

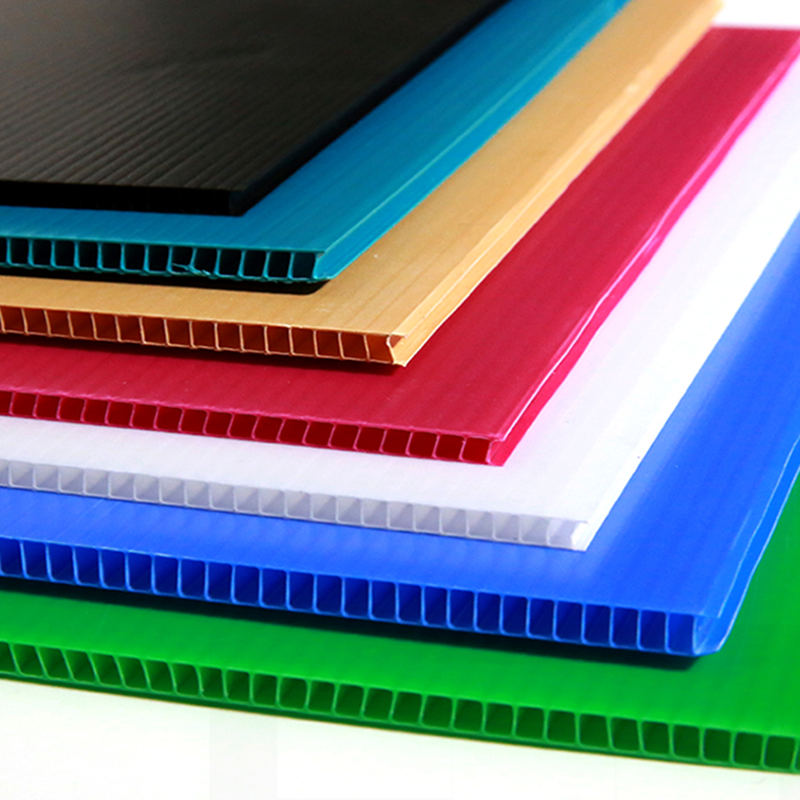

When it comes to reliable and durable materials, I often recommend honeycomb plastic sheets. These versatile sheets, manufactured in China, are perfect for a range of applications, from automotive components to packaging solutions. The unique honeycomb structure provides excellent strength while remaining lightweight, making them an ideal choice for those looking to cut down on material weight without sacrificing durability. As a buyer, I appreciate the cost-effectiveness these sheets offer. They’re not just easy to work with, but they also come in various sizes and thicknesses to fit any project needs. Plus, sourcing from a trusted manufacturer in China ensures that I get consistent quality and competitive pricing. Whether I’m involved in construction or design, I can always rely on honeycomb plastic sheets to deliver outstanding performance and efficiency. If you’re aiming to enhance your production process, consider incorporating these sheets into your supply chain.

Honeycomb Plastic Sheet Pioneers in the Field Where Innovation Meets 2025

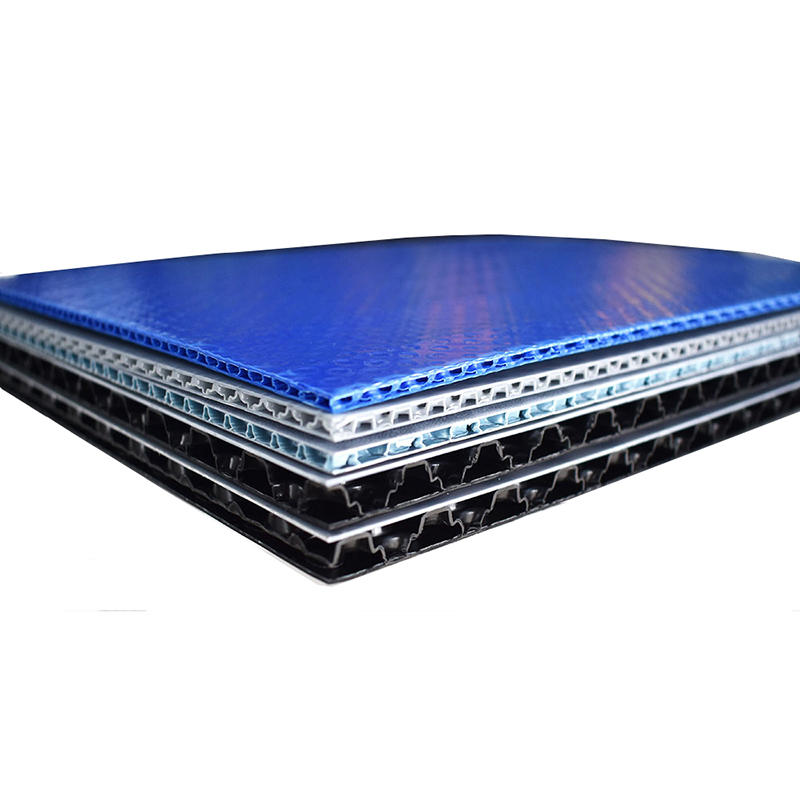

In the rapidly evolving world of materials, honeycomb plastic sheets have emerged as a revolutionary solution in various industries. Their unique structure not only provides outstanding strength-to-weight ratios but also enhances durability and insulation properties. As we approach 2025, the demand for innovative and sustainable materials is more pressing than ever. Honeycomb plastic sheets offer an ideal combination of versatility and performance, making them a top choice for global procurement in construction, automotive, packaging, and many other sectors. The production of honeycomb plastic sheets is rooted in cutting-edge technology, ensuring that they meet the highest standards in terms of quality and environmental safety. By utilizing advanced manufacturing processes, these sheets can be customized to suit a wide range of applications, thus effectively addressing diverse customer needs. As businesses look to enhance their product offerings and ensure compliance with increasingly stringent regulations, adopting honeycomb plastic sheets can lead to significant competitive advantages. With a clear emphasis on innovation, sustainability, and functionality, honeycomb plastic sheets stand at the forefront of materials technology. As procurement professionals seek reliable solutions that deliver genuine value, investing in this material not only provides immediate benefits but also contributes to long-term goals of efficiency and environmental responsibility. Embrace the future of materials with honeycomb plastic sheets and discover the myriad ways they can elevate your business in an ever-changing marketplace.

Honeycomb Plastic Sheet Pioneers in the Field Where Innovation Meets 2025

| Application Area | Material Type | Thickness (mm) | Weight (kg/m²) | Thermal Conductivity (W/mK) | Flame Retardant Rating |

|---|---|---|---|---|---|

| Automotive | Polypropylene | 5 | 1.5 | 0.035 | B2 |

| Construction | PVC | 10 | 2.0 | 0.084 | B1 |

| Packaging | Polyethylene | 3 | 1.0 | 0.030 | B2 |

| Aerospace | Carbon Fiber | 8 | 1.8 | 0.045 | A |

| Electronics | Polycarbonate | 6 | 1.4 | 0.025 | B1 |

Related Products