Honeycomb Sandwich Panel Manufacturer in China: Quality & Innovation

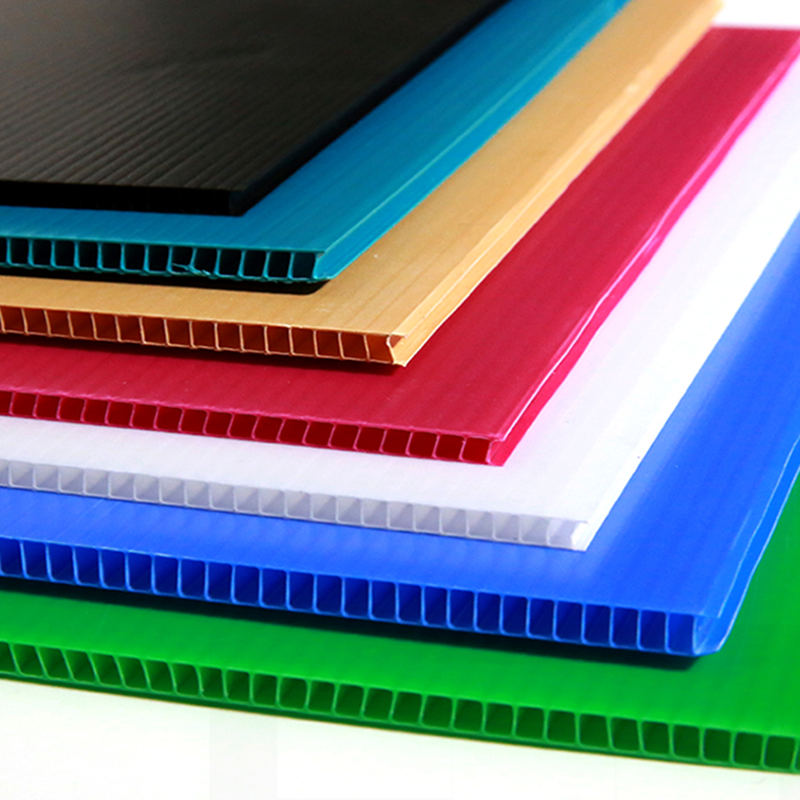

If you're searching for high-quality Honeycomb Sandwich Panels, you're in the right place. Our products are designed with durability and efficiency in mind, making them perfect for various applications in construction and insulation. We pride ourselves on being a leading manufacturer in China, providing top-notch materials that meet industry standards. We know that every project needs reliable solutions, and our Honeycomb Sandwich Panels offer excellent thermal insulation, lightweight properties, and easy installation. Whether you’re involved in industrial, commercial, or residential projects, you can trust our panels to deliver the performance you need. With our competitive pricing and commitment to customer satisfaction, I’m here to ensure you find exactly what you need. Connect with us today to discuss how our products can enhance your next project and provide long-lasting benefits. Let’s work together to meet your specific requirements in the most efficient way possible!

Honeycomb Sandwich Panel in 2025 Where Innovation Meets 2025

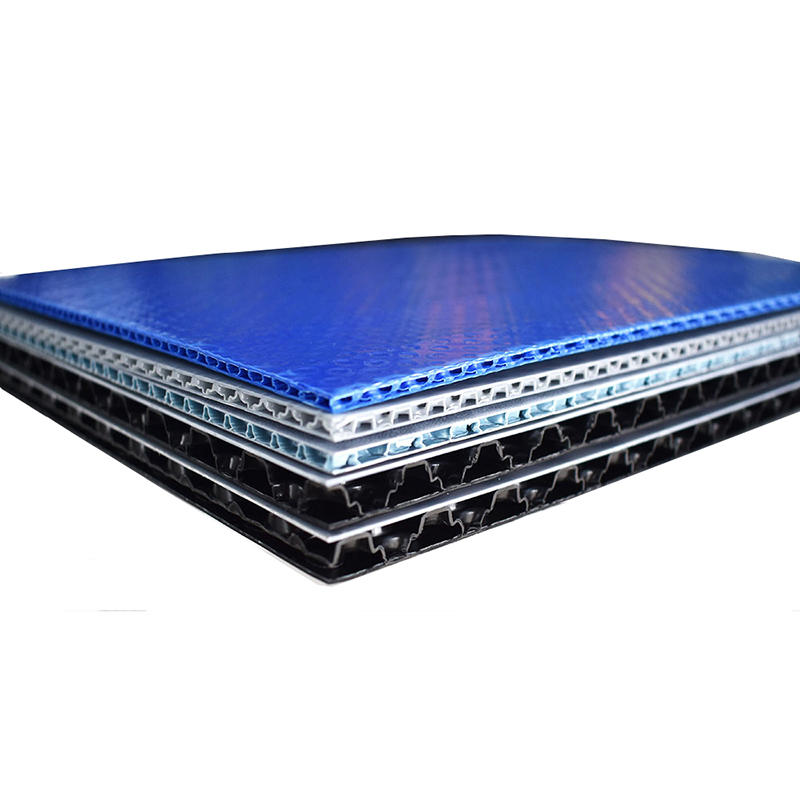

In 2025, the world of construction materials is set to witness significant advancements with the introduction of innovative solutions like honeycomb sandwich panels. These panels are not just about structural integrity; they represent a fusion of lightweight design, thermal efficiency, and sustainable construction practices, making them an appealing choice for global buyers. As industries increasingly recognize the importance of reducing carbon footprints, honeycomb sandwich panels emerge as a versatile alternative, suited for various applications ranging from commercial buildings to residential complexes. The key to the honeycomb sandwich panel’s appeal lies in its unique structure. Comprising two outer layers and a lightweight core resembling a honeycomb, this design maximizes strength while minimizing weight. This balance is crucial for modern construction, as it facilitates easier handling, reduced shipping costs, and less material waste. Furthermore, these panels offer excellent insulation properties, contributing to energy savings and lower operational costs for end-users. As sustainability becomes a priority in the construction sector, investing in such innovative materials reflects a commitment to environmental responsibility without compromising quality. As we move further into 2025, embracing innovation through materials like honeycomb sandwich panels is not just advantageous; it's essential. For procurement professionals seeking to stay ahead of the market, selecting suppliers who prioritize cutting-edge technology and sustainable practices will be key. By choosing solutions that embody both efficiency and environmental stewardship, businesses can meet the demands of modern construction while also contributing to a greener future.

Honeycomb Sandwich Panel in 2025 Where Innovation Meets 2025

| Dimension (mm) | Material | Thermal Conductivity (W/m·K) | Applications | Sustainability Rating |

|---|---|---|---|---|

| 60 x 1000 x 2000 | Aluminum | 0.15 | Wall Panels | A+ |

| 80 x 1200 x 3000 | Steel | 0.10 | Roofing | A |

| 100 x 1000 x 2500 | Fiber Reinforced Polymer | 0.12 | Insulation | A++ |

| 50 x 800 x 3000 | Wood-fiber | 0.20 | Interior Panels | A+ |

Related Products