Top Plastic Honeycomb Panel Manufacturer in China for Quality Solutions

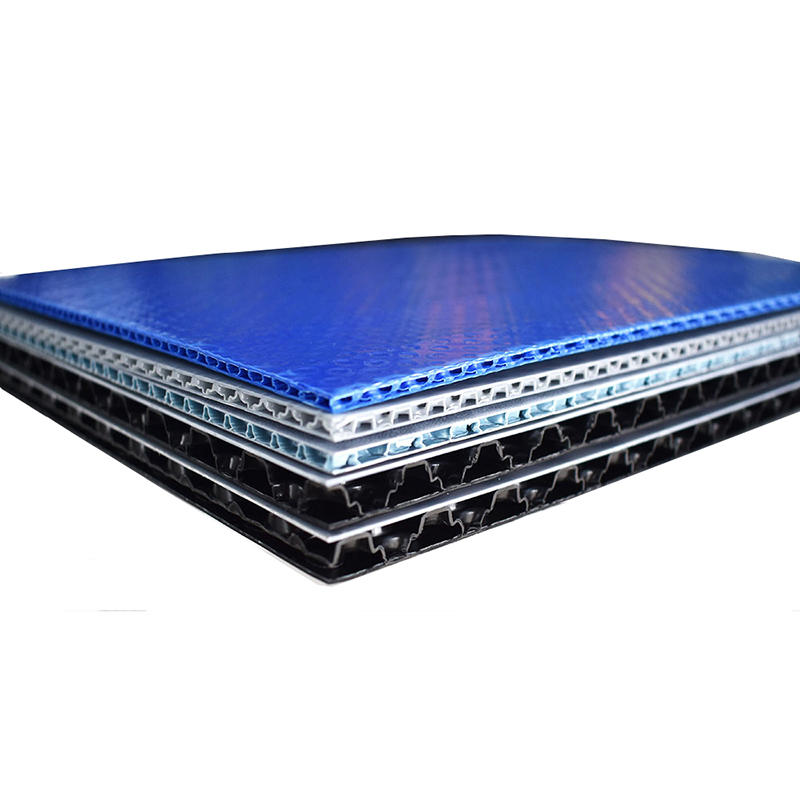

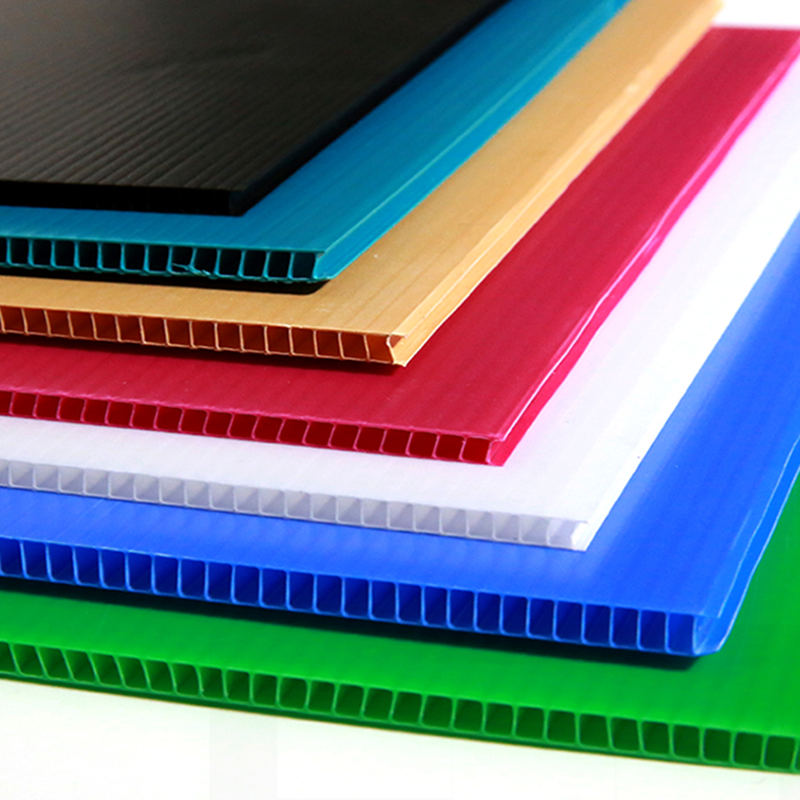

When it comes to high-quality Plastic Honeycomb Panels, I know how important it is to source from a reliable manufacturer in China. These panels are designed to provide exceptional strength while being lightweight, making them perfect for diverse applications in construction, transportation, and packaging. I’m impressed by how our panels offer excellent insulation properties and durability, ensuring that they withstand the test of time. Whether you need them for walls, ceilings, or any custom applications, I can help you find exactly what you need. With our extensive experience in the industry, we ensure every panel meets strict quality standards and is competitively priced. Partnering with a trustworthy manufacturer is key, and I’m here to provide you with the best solutions to meet your business needs. If you’re looking for efficiency and reliability, let’s connect to discuss your project requirements and explore how our Plastic Honeycomb Panels can benefit your operations.

Plastic Honeycomb Panel Is The Best Trusted by Pros

When it comes to innovative building materials, plastic honeycomb panels have emerged as a game-changer, recognized and trusted by professionals in various industries worldwide. These lightweight yet durable panels offer exceptional strength-to-weight ratios, making them ideal for applications ranging from construction and industrial design to transportation and packaging. With their unique honeycomb structure, they provide superior insulation properties while ensuring easy handling and installation, which promotes efficiency on construction sites and in manufacturing processes. Another critical advantage is their resistance to moisture, chemicals, and UV light, which enhances longevity and reduces maintenance costs. As sustainability becomes increasingly vital, the recyclable nature of plastic honeycomb panels aligns perfectly with eco-friendly initiatives. They contribute to energy savings and waste reduction, making them an attractive choice for environmentally conscious projects. Trusted by experts, these panels not only meet rigorous performance standards but also offer flexibility in design, allowing for customized solutions tailored to specific needs. As global sourcing continues to evolve, staying ahead of trends is crucial for procurement professionals. The shift towards lightweight and sustainable materials underscores the importance of integrating plastic honeycomb panels into various applications. By considering these trusted solutions, businesses can enhance their operational efficiency, reduce costs, and contribute positively to sustainability efforts, ultimately ensuring a competitive advantage in the ever-demanding marketplace.

Plastic Honeycomb Panel Is The Best Trusted by Pros

| Feature | Description | Application | Pros | Cons |

|---|---|---|---|---|

| Lightweight | Weighs significantly less than traditional materials. | Interior walls, portable structures. | Easy to transport and install. | Can be less durable under extreme conditions. |

| Thermal Insulation | Provides excellent insulation properties. | Building facades, cold storage facilities. | Energy-efficient solution. | Higher initial investment compared to some materials. |

| Moisture Resistance | Resistant to water damage and mold growth. | Wet environments, outdoor applications. | Longevity in humid conditions. | Not suitable for load-bearing structures. |

| Eco-Friendly | Can be made from recyclable materials. | Green building projects. | Supports sustainability initiatives. | Availability of sustainable options may vary. |

| Easy Fabrication | Can be easily cut, shaped, and assembled. | Custom applications in various industries. | Versatile in design. | Requires skilled labor for large projects. |

Related Products