China Manufacturer of Polypropylene Honeycomb Core Panels for Optimal Use

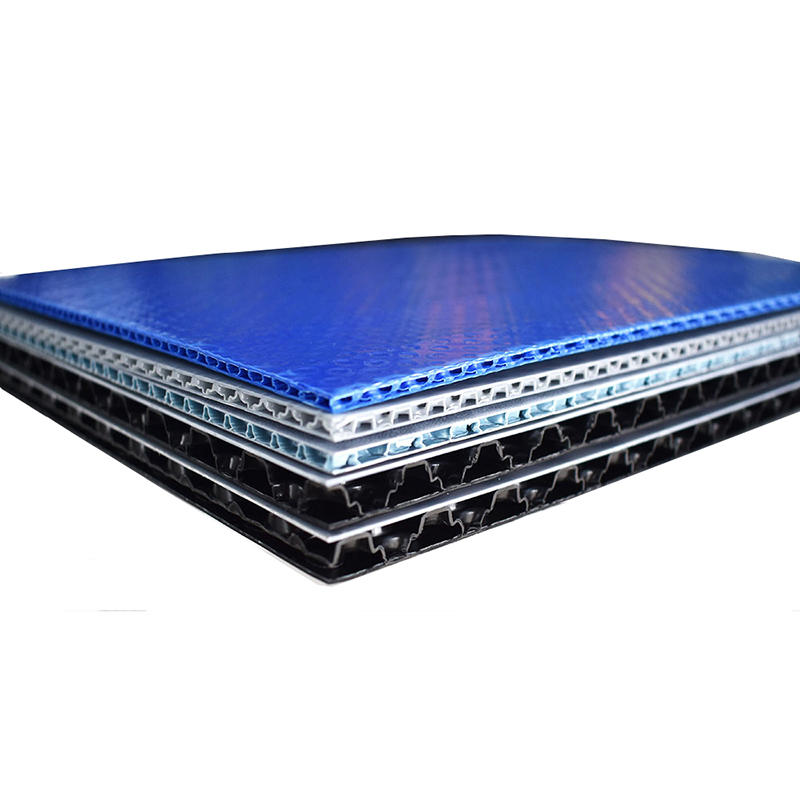

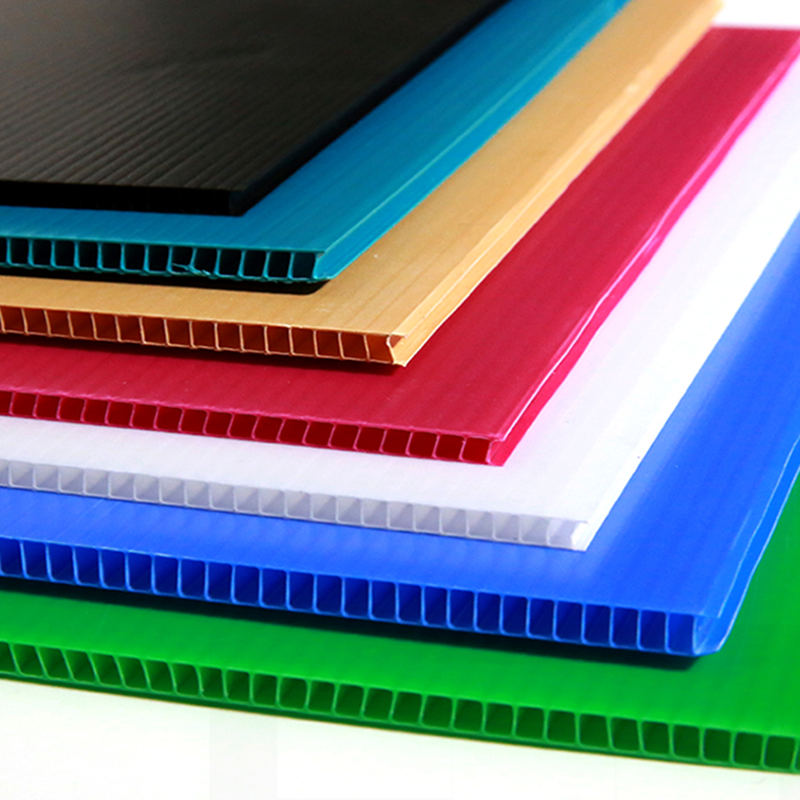

When it comes to lightweight, durable materials, I’ve found that polypropylene honeycomb core panels are unbeatable. These panels are designed for strength and versatility, making them perfect for a variety of industrial applications. Sourced directly from leading manufacturers in China, they offer incredible insulation properties and excellent resistance to moisture and chemicals. I appreciate how these honeycomb panels are easy to work with, cutting down on production times without sacrificing quality. Plus, their eco-friendly nature adds an extra layer of appeal for businesses looking to reduce their carbon footprint. If you’re considering options to enhance your projects, I highly recommend exploring polypropylene honeycomb core panels. They really could be the game-changer you need!

Polypropylene Honeycomb Core Panels Winning in 2025 Supplies the World\u2019s Top Brands

In the rapidly evolving landscape of materials technology, polypropylene honeycomb core panels are emerging as a game-changer for industries worldwide. By 2025, these innovative panels are set to revolutionize the way products are manufactured and assembled, providing unparalleled benefits in terms of strength, weight savings, and environmental sustainability. With an increasing emphasis on efficiency and performance, major global brands are turning to these advanced solutions to enhance their product offerings. The lightweight yet durable nature of polypropylene honeycomb core panels makes them ideal for a variety of applications, from aerospace and automotive to construction and furniture. Their exceptional structural integrity not only ensures longevity but also contributes to energy savings during transportation and installation. As companies strive to reduce their carbon footprint, these eco-friendly materials stand out for their recyclability and reduced resource consumption in production. Moreover, the versatility of polypropylene honeycomb core panels allows for customization to meet specific industry needs. As a result, brands can achieve a competitive edge by integrating these panels into their processes. With a commitment to innovation and quality, embracing these materials is not just a trend, but a strategic move towards a sustainable future in manufacturing and design.

Polypropylene Honeycomb Core Panels Winning in 2025 Supplies the World’s Top Brands

| Panel Type | Weight (kg/m²) | Strength (N/mm²) | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|

| Standard Panel | 2.5 | 25 | 0.03 | Construction, Automotive |

| High-Strength Panel | 3.0 | 35 | 0.04 | Aerospace, Marine |

| Fire-Resistant Panel | 2.8 | 30 | 0.02 | Interior Walls, Transport |

| Lightweight Panel | 1.8 | 20 | 0.05 | Packaging, Furniture |

Related Products