China Manufacturer of Polypropylene Honeycomb Core - Competitive Prices

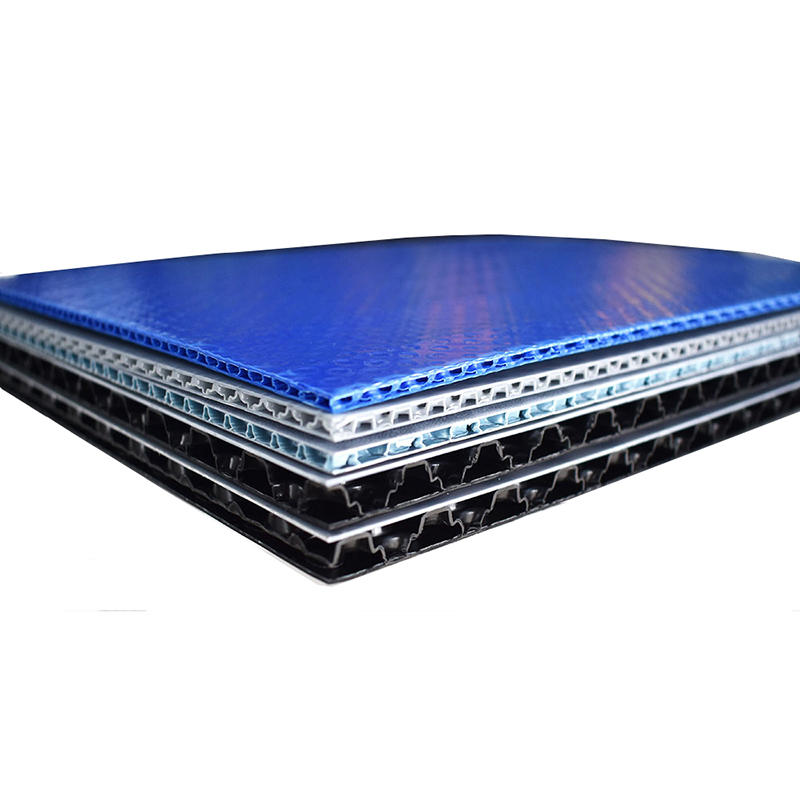

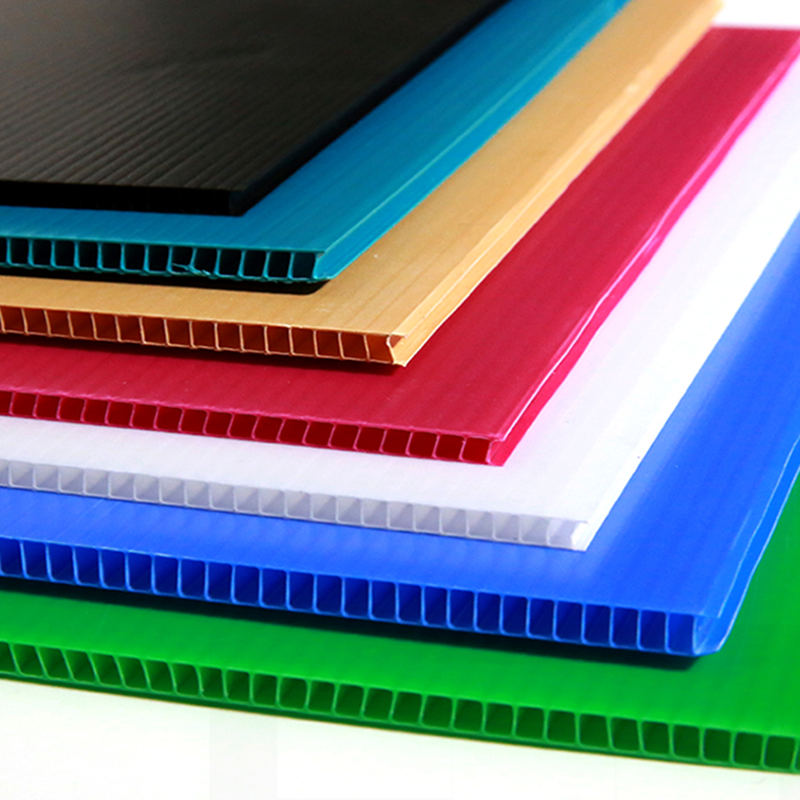

As a seasoned professional in the field, I understand how crucial it is to find the best Polypropylene Honeycomb Core at a competitive price. Our products, manufactured in China, offer unmatched quality and durability, perfect for a variety of applications. I've seen the transformation in projects when utilizing our honeycomb cores; they provide lightweight strength without sacrificing performance. When it comes to sourcing, I know how important it is to partner with reliable manufacturers. Our team prides itself on strict quality control and innovative methods to ensure you receive top-notch materials. Pricing is always a key consideration, and we strive to offer the best Polypropylene Honeycomb Core Price in the market, tailored to meet your specific needs. Let’s connect and explore how our solutions can add value to your projects while optimizing your costs. Your satisfaction is our priority, and I’m here to assist you every step of the way!

Polypropylene Honeycomb Core Price Now Trending More Than a Supplier - A Partner

The polypropylene honeycomb core market is experiencing a significant shift, evolving from a mere supplier relationship to a more integrated partnership approach. This change reflects the growing demand for innovative materials that not only meet quality standards but also support sustainable practices. As global buyers seek to optimize their supply chains, establishing strong partnerships with manufacturers who understand their unique needs is becoming crucial. The versatility and lightweight nature of polypropylene honeycomb cores make them ideal for a wide range of applications, from automotive to construction. By focusing on collaboration and transparency, suppliers are better positioned to provide tailored solutions that enhance product performance and reduce environmental impact. This trend emphasizes the importance of communication and shared goals in driving long-term success for both buyers and suppliers. As the industry continues to evolve, those who adapt to this new paradigm will benefit most. Engaging with suppliers as partners fosters innovation and creates opportunities for developing advanced materials that cater to the ever-changing market landscape. Globally minded purchasers should consider this approach, ensuring that they are positioned to leverage the full potential of this dynamic sector.

Polypropylene Honeycomb Core Price Now Trending More Than a Supplier - A Partner

| Material Type | Thickness (mm) | Density (kg/m³) | Application | Market Trend |

|---|---|---|---|---|

| Polypropylene | 10 | 45 | Aerospace | Increasing |

| Polypropylene | 20 | 50 | Automotive | Stable |

| Polyethylene | 15 | 40 | Construction | Decreasing |

| Polypropylene | 25 | 55 | Marine | Increasing |

| Polypropylene | 30 | 60 | Packaging | Stable |

Related Products