China Manufacturer of Polypropylene Honeycomb Sandwich Panels

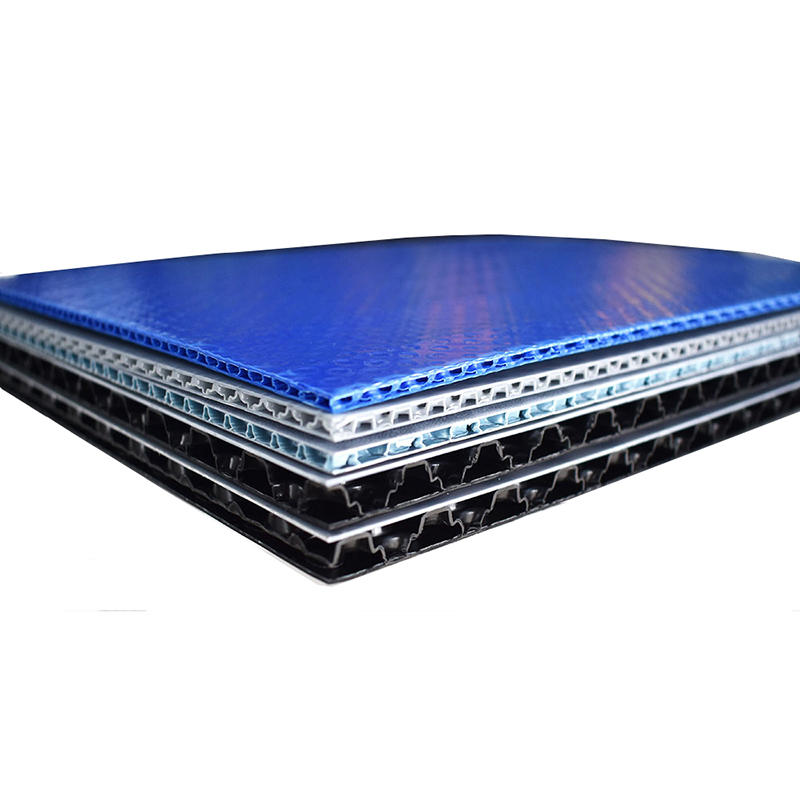

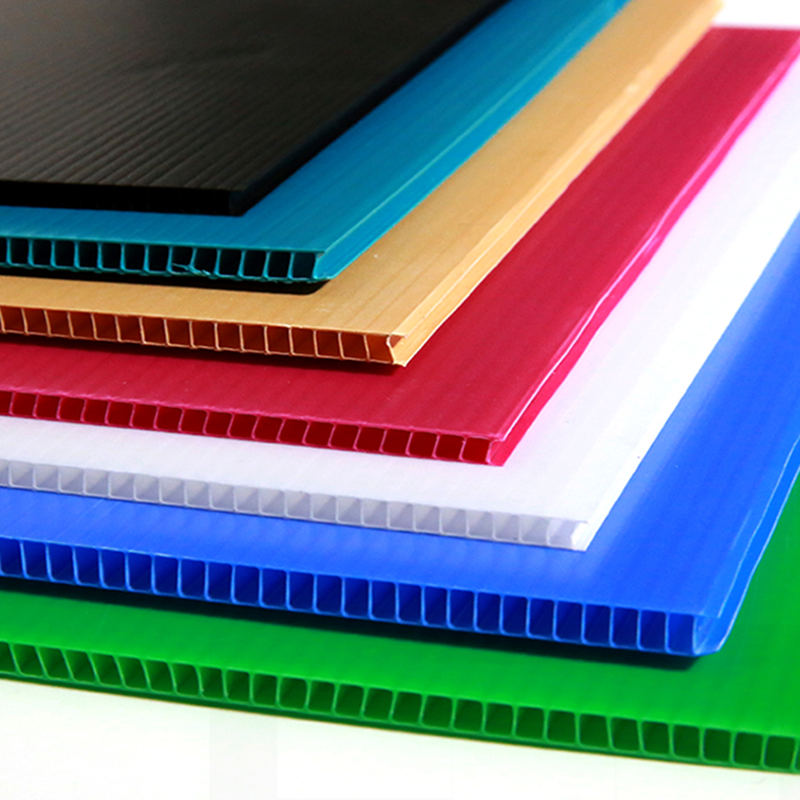

When I first encountered Polypropylene Honeycomb Sandwich Panels, I was amazed by their lightweight yet durable properties. These panels are perfect for various applications, from construction to automotive industries. Made with high-quality materials, they offer excellent thermal insulation and soundproofing, making them an ideal choice for projects that require efficiency and quality. As a leading manufacturer in China, I understand the importance of reliability and performance. My focus is on providing exceptional products that meet global standards. The unique honeycomb structure not only reduces weight but also enhances strength, allowing for innovative designs without compromising on quality. Whether you're looking to optimize your production processes or seeking materials that stand the test of time, these panels could be just what you need. I take pride in offering solutions tailored to your specific needs, ensuring you achieve your project goals with ease. Let’s connect and explore how we can bring your ideas to life!

Polypropylene Honeycomb Sandwich Panels Sets the Industry Standard Service Backed by Expertise

In the evolving world of construction and manufacturing, the demand for lightweight yet durable materials has reached new heights. Enter polypropylene honeycomb sandwich panels, a game-changer in the industry that sets a new standard for quality and performance. These panels, characterized by their unique structure, deliver exceptional strength-to-weight ratios while offering outstanding thermal and sound insulation properties. As global procurement professionals seek innovative solutions that enhance efficiency and reduce costs, these panels emerge as an ideal choice for a wide range of applications, from transportation to building facades. What distinguishes these honeycomb sandwich panels is not only their superior functionality but also the expertise that backs their development and application. With a commitment to rigorous testing and quality control, manufacturers ensure that every panel meets international safety and performance standards. As a result, procurement managers can rely on a product that not only meets industry benchmarks but also supports sustainable construction practices. The lightweight nature of these panels facilitates easier handling and installation, thus reducing labor costs and project timelines. As industries worldwide prioritize efficiency and sustainability, the use of polypropylene honeycomb sandwich panels serves as a strategic advantage. By opting for this advanced material, global buyers not only enhance their product offerings but also align with contemporary market demands for environmentally friendly solutions. Investing in these innovative panels means securing a brighter, more efficient future for construction and manufacturing, backed by unparalleled expertise and quality assurance.

Polypropylene Honeycomb Sandwich Panels Sets the Industry Standard Service Backed by Expertise

| Specification | Value |

|---|---|

| Panel Thickness | 20 mm |

| Core Material | Polypropylene Honeycomb |

| Face Skin Material | Aluminium Composite |

| Density | 450 kg/m³ |

| Thermal Conductivity | 0.035 W/m·K |

| Fire Rating | Class B2 |

| Sound Insulation | 29 dB |

| Warranty Period | 10 years |

Related Products